Computer Aided Manufacturing

The Palla-Tech gained a lot of experience not only on the world of CAD (Computer Aided Design), but on CAM (Computer Aided Manufacturing) as well.

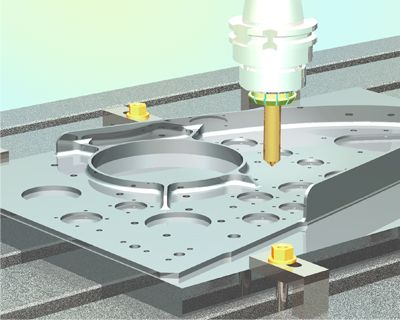

During Computer Aided Manufacturing (CAM), we create the numerical control program (CNC-Program) for different machinery by the help of a computer system. Using the so generated CNC-Program, the machinery is able to perform the tasks to manufacture the desired parts.

CAM helps us to create the part from an optimum sized raw material as fast as possible by the best CNC-Program.

Palla-Tech is able to manufacture the CAD models as soon as they are ready, so the time consuming creation of manufacturing drawings can be saved.

The CAM systems used by Palla-Tech are not only capable to manufacture their own CAD models, but as they also contain a high end import subsystem, are able to convert and process foreign models as well. The standard types are also importable such as igs, stp, parasolid.

After creating the toolpaths and the CNC-Program, it is desirable to create some kind of documentation as well. Palla-Tech is capable of creating the documentation in the specific form and standard of our client, so by the manufacturing process the unnecessary times of interpreting the foreign documentation can be eliminated.

One common feature of all CAM systems is, that the generated 3D toolpaths must be converted into the native language of the manufacturing machines. This process is called postprocessing. The different types of machinery use several native languages, so a good postprocessor is essential. Our CAM systems have currently postprocessors for several native languages. That means, we are able to create the CNC-Program for a lot of types of machines. But it also happens, that we don not have a specific type of postprocessor. In that case, we are also capable of creating a postprocessor for that machine, based on an existing CNC-Program. We can generate CNC-Programs for rare native languages as well.